G e t F r e e Q u o t a t i o n

Quality Control and Inspection

At PWR TOOLS, our commitment to quality control and inspection sets us apart in the power tools industry. We understand that our customers depend on our products to get the job done, and we aim to consistently exceed their expectations by delivering the highest quality and most reliable power tools on the market.

Our quality control and inspection process is managed by a team of experienced quality management professionals and technical experts. With their extensive experience and expertise, we ensure that each power tool meets our rigorous standards for quality, reliability, and safety.

As a trusted power tools manufacturer, we take quality control and inspection seriously. Our carefully designed process guarantees that every tool we produce meets the highest standards of performance and durability, giving our customers the confidence they need.

Process of Quality Control and Inspection

Our quality control and inspection process begins with the careful selection of raw materials and extends throughout production and shipping. We rigorously evaluate and source only high-quality materials that meet or exceed industry standards for safety and performance. During production, we adhere to stringent guidelines, conducting regular inspections and tests to verify that each tool meets our exacting standards for performance and durability. Finally, after the product is completed, we perform comprehensive inspections to confirm that it functions flawlessly and meets our customers' specific requirements and expectations.

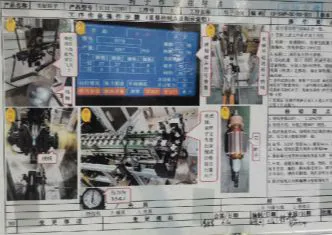

First-Article Inspections (FAI) are performed prior to mass production. Product properties are measured and compared with specifications to verify quality matches.

In-Process Inspections (IPI) ensure that the processes and techniques used to manufacture power tools are followed.

Pre-Shipment Inspections (PSI)verify the conformity of power tools to specifications before shipping. Inspectors evaluate workmanship, functionality, packaging, labeling, and other criteria as required.

Container Loading Supervision (CLS) ensures that proper methods are employed during product loading, and counts are verified on-site.

Sorting services are used to inspect production and detect quality issues or perform rework operations.

Inspection checklists for Power tools quality control

Appearance check

Assembly check: complete/ tight and tough

Accessory fitting

Foreign object

Tools Overall Test: durability test, temperature rise test, working condition test

Function test

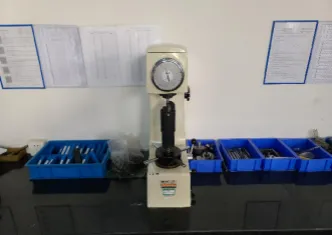

Parts Inspection (Including Purchased Raw Materials)

Internal check

Overall Production Line Inspection

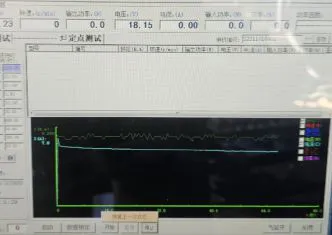

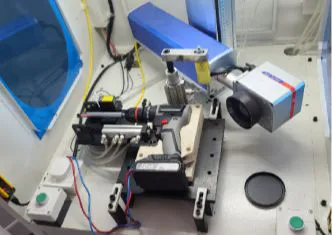

Speed Test(RPM)

Hi-pot test

No load Power consumption/ Load Power test consumption

Power cord parameter inspection: material, cross-sectional area, exposed length, applicable voltage

Tensile and bending test for power cord

Cool motor resistance test

Running test: smooth running/ noise within standard/ no obvious vibration etc

Package/Carton Drop test

Barcode scan test

Rub test for logo etc

Tools Overall Test-Durability Test, Temperature Rise Test, Working Condition Test

Overall Production Line Inspection

Parts Inspection (Including Purchased Raw Materials)

Unlock The Potential of Your Business With PWRTOOLS.

Fields marked with an asterisk (*) are required. We will respond to you as soon as possible. You can also reach us via email at info@pwrtools.com.

Let's power up your success together!

Get Your Free Catalog

Please provide your contact details below, and we’ll reach out to you shortly.